Understanding Progressive Dies

What are Progressive Dies?

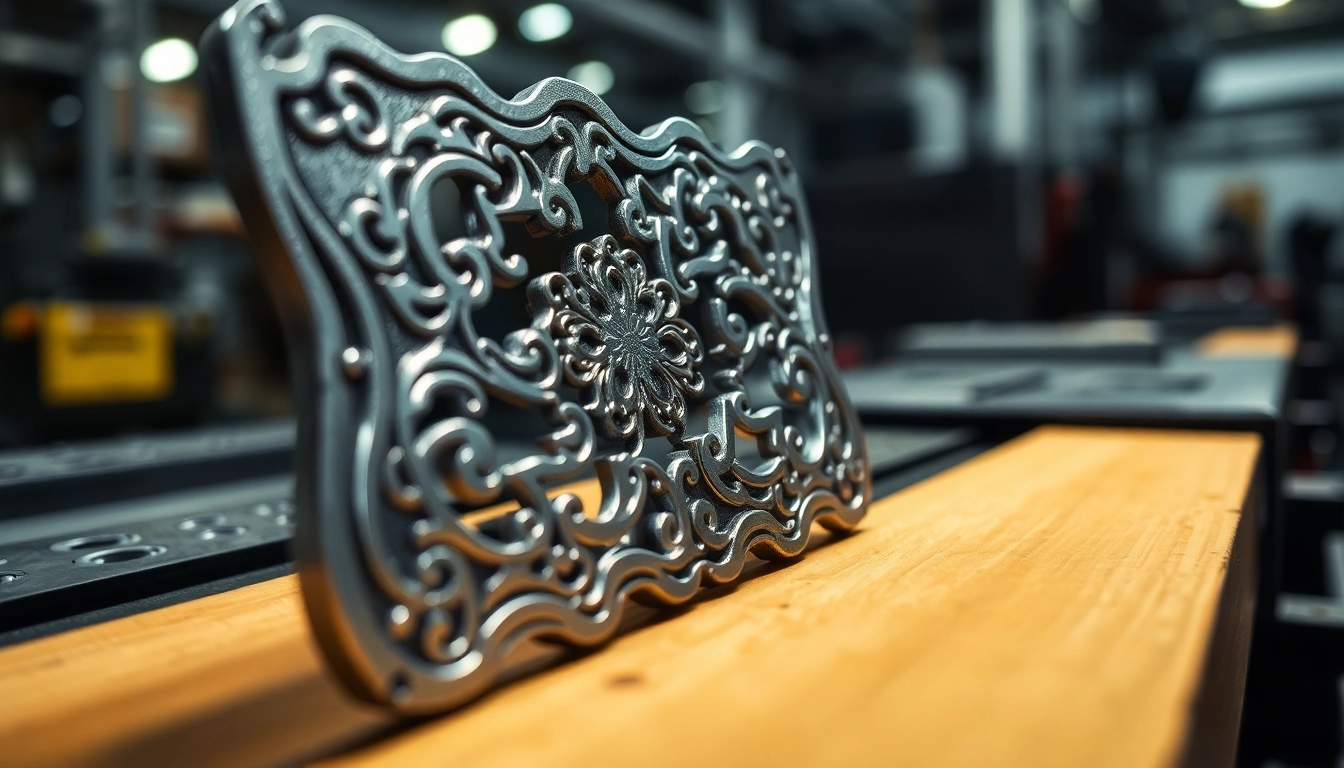

Progressive dies are advanced tooling solutions designed to enhance the efficiency of metal stamping processes. Unlike traditional dies, which may require multiple stages to achieve the desired component, progressive dies allow for the complete manufacturing of parts in a single pass through the press. This innovative approach not only significantly reduces production time but also minimizes material waste, making it an integral part of modern manufacturing.

At Dongguan Chaoyang Hardware Products Co., Ltd., we specialize in creating high-precision Progressive Dies that cater to a variety of industrial applications. With our extensive experience since 2005, we focus on delivering exceptional tooling solutions that meet the demanding standards of today’s industries.

Applications of Progressive Dies in Industry

Progressive dies find applications across a wide array of industries, including automotive, electronics, medical devices, and consumer goods. In the automotive sector, for instance, these dies are used for producing components such as brackets, clips, and shielding parts that require precise specifications. The electronics industry benefits from progressive dies due to their ability to create intricate parts like connectors and circuit components with tight tolerances.

Moreover, the medical field relies on the precision and reliability of progressive dies for manufacturing components that often dictate device performance, such as implants, surgical instruments, and diagnostic tools. The versatility and efficacy of progressive dies make them an invaluable resource for manufacturers seeking to enhance their production capabilities.

Benefits of Using Progressive Dies

One of the most significant benefits of progressive dies is the reduction of production costs. By streamlining the manufacturing process, companies can achieve higher output rates while minimizing labor and operational costs. Additionally, the inherent efficiency of progressive die design leads to less scrap material, further decreasing waste.

Another advantage is the enhanced precision and quality control that progressive dies offer. The integration of multiple operations within a single tool ensures that all components are manufactured consistently, maintaining stringent quality standards. This aspect is critical in industries where even the slightest deviations can result in product malfunctions or safety hazards.

Furthermore, progressive dies facilitate greater flexibility in design. Manufacturers can easily adapt the die to accommodate changes in specifications or materials, ensuring that their production lines can quickly respond to market demands.

The Design Process of Progressive Dies

Key Elements in Die Design

The design of progressive dies requires a thorough understanding of both the component specifications and the material properties. Key elements in die design include die layout, material flow, and stripping mechanisms. The die layout must efficiently sequence operations to ensure smooth material flow through each stage of the stamping process.

Material choice also plays a crucial role in die design, as different materials can withstand varying levels of pressure and wear. For instance, hardened tool steels are commonly used for their durability, while aluminum might be preferred for lighter components. The design process blends engineering expertise with practical considerations to create effective and efficient progressive dies.

Steps in Creating Effective Progressive Dies

The creation of effective progressive dies follows a series of essential steps:

- Initial Design and Prototyping: This stage involves collaborating with clients to understand their specific needs, followed by the development of initial die designs and prototypes.

- Simulation and Analysis: Advanced simulation software allows engineers to analyze the die design under various conditions, ensuring that the proposed die will perform as intended.

- Fabrication: Once approved, the die is fabricated using state-of-the-art machinery, ensuring precision across all components.

- Testing and Validation: Rigorously testing the die in actual production scenarios helps validate its effectiveness and durability.

- Final Adjustments: Any necessary modifications based on testing results are made to optimize performance.

Importance of Collaboration in the Design Process

Collaboration stands as a cornerstone of the progressive die design process. Engaging with clients throughout the design journey allows manufacturers to align their offerings with specific requirements. Additionally, cooperation with engineers, material specialists, and quality assurance teams ensures a well-rounded approach to die design. By fostering an environment of communication and teamwork, we at Chaoyang embody the principle of putting people first, ensuring that every stakeholder contributes to the success of the final product.

Progressive Dies vs. Other Die Types

Comparison with Compound Dies

While both progressive dies and compound dies serve the purpose of forming metal components, they operate differently. Compound dies perform multiple operations in a single stroke but generally do not allow for the continuous processing of materials, as seen with progressive dies. Instead, they require a specific sequence to be performed, often leading to longer cycle times.

On the other hand, progressive dies can execute complex manufacturing tasks in one continuous motion, providing higher efficiency and improved output rates. This makes progressive dies a more advantageous choice where rapid production and precision are crucial.

Advantages over Single-Hit Dies

Single-hit dies, as the name implies, perform one operation per stroke. While they can be useful for simple components, they tend to be less efficient and can create bottlenecks in production when more complex shapes are required. Progressive dies circumvent this limitation by allowing multiple operations, which significantly increases throughput.

Moreover, the ability to process the entire part in one pass reduces the risk of errors associated with transferring materials between multiple tools, leading to higher quality and consistency in the final products.

When to Choose Progressive Dies

Choosing progressive dies is advisable when manufacturing high volumes of precision parts that require intricate designs and tight tolerances. Industries that demand rapid production and efficiency should consider this die type, particularly for components with complex geometries or those that integrate multiple features.

Additionally, if a project necessitates minimal material waste and operational costs, investing in progressive dies can be highly beneficial. They are ideally suited for applications with high production rates and stringent quality standards.

Quality Control in Progressive Die Manufacturing

Implementing CMM Inspections

Quality control is paramount in the manufacturing of progressive dies, and one of the key methods we employ is Coordinate Measuring Machine (CMM) inspections. CMMs enable precise measurement of the die components and ensure they meet the specified tolerances. This technological assurance helps catch discrepancies early in the process, allowing for timely corrections before full production begins.

Ensuring Material Integrity

Another aspect of quality control revolves around ensuring the integrity of the materials used in die fabrication. At Chaoyang, we source high-quality materials to maintain the durability and reliability of our progressive dies. This includes rigorous testing of material properties such as hardness and tensile strength, confirming that they align with the expected performance criteria.

Testing for Precision and Longevity

Testing is not confined to initial inspections; it continues throughout the die’s lifecycle. We conduct extensive try-out tests during production runs, allowing us to gauge the die’s performance under actual working conditions. This step guarantees that our progressive dies can withstand operational challenges while maintaining their precision and effectiveness over time.

Future Trends in Progressive Die Technology

Innovations in Material Usage

The landscape of progressive die technology is continuously evolving, with innovations in material usage playing a significant role. Future advancements may include the integration of lightweight alloys and composites that offer both strength and reduced weight, enabling the manufacture of more versatile and efficient components.

We are observing an increasing trend toward the use of advanced coatings and treatments that enhance wear resistance, further extending the lifespan of progressive dies and reducing maintenance costs for manufacturers.

Advances in CNC Machining and Automation

As CNC machining technology progresses, we expect to see greater automation within die manufacturing processes. Enhanced automation will minimize human error, increase throughput, and allow for real-time monitoring of manufacturing conditions. This shift also aligns with the broader industry trend toward Industry 4.0, where smart factories employ interconnected systems for more efficient production lines.

Sustainability Considerations in Die Design

In today’s increasingly eco-conscious environment, sustainability is gaining focus in die design and manufacturing. Future trends will prioritize designs that reduce energy consumption during production and enhance recyclability at the end of the die’s life cycle. At Dongguan Chaoyang Hardware Products Co., Ltd., we are committed to integrating sustainable practices into our manufacturing processes, ensuring that our progressive dies not only meet performance standards but also contribute positively to the environment.